Check out our recently completed hi-tech projects

Donec pretium vulputate sapien nec sagittis aliquam malesuada. Adipiscing enim eu turpis egestas vitae tempus pretium.

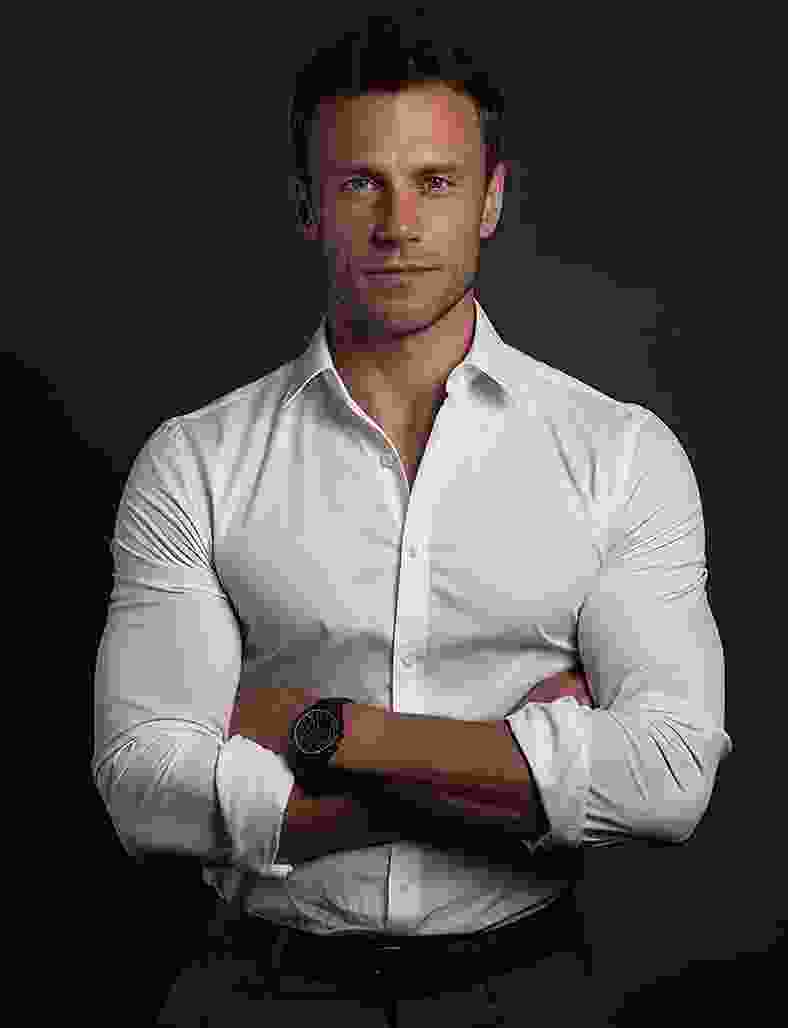

Thomas

Architect

Et magnis dis parturient montes nascetur. Neque laoreet suspendisse interdum consectetur libero id faucibus nisl. Arcu non odio acinia.

David

Designer

Euismod nisi porta lorem mollis aliquam ut porttitor. A erat nam at lectus urna. Magna fermentum iaculis eu non. Condimentum.

Arnold

Chief Engineer

Tempus egestas sed sed risus pretium quam vulputate dignissim. Eget magna fermentum iaculis eu non diam. Pretium lectus quam id.

Laara

CEO

Our Service

Automation Makes Everything Easier In Process Logistics

Libero enim sed faucibus turpis. Vestibulum morbi blandit cursus risus at ultrices mi. Amet porttitor eget dolor morbi non arcu risus. Dolor sed viverra ipsum nunc. Consectetur adipiscing elit duis tristique sollicitudin commodo.

- Amet dictum sit amet justo donec enimties.

- Convallis a cras semper auctor neque vit.

- Vel pretium lectus quam id leo in vitae. Feugiat scelerisque varius morbi enim nunc.

- Etiam dignissim diam quis enim lobortis sceleri.

- Vel elit scelerisque mauris pellentesque.

- At Parco Pearl Gas, we prioritize the quality of our product (i.e., LPG) to ensure the highest standards of safety and performance. Our rigorous quality control process involves multiple checks throughout the day.

- We utilize hydrometers to measure the specific gravity of our LPG, ensuring they meet the required standards. Additionally, we collect samples from bowsers arriving from various sources, including refineries and fields, to verify their specific gravity and acceptability.

- To further guarantee the quality of our LPG, we engage recognized third-party testing services to conduct testing in accordance with GPA standards. These tests check on sulfur content, specific gravity, and Reid vapor pressure, providing an added layer of assurance.

- By upholding these quality control measures, we demonstrate our commitment to delivering high-quality LPG that meet the expectations of our customers.

- We recognize the importance of ensuring the integrity and safety of our LPG cylinders. To achieve this, we have implemented a rigorous cylinder quality check process at our plant.

- Our cylinders are being manufactured as international DOT and EN standards, with a detailed third-party inspection at each manufacturing stage, to ensure best quality.

- Every cylinder that arrives at our facility for filling undergoes a thorough physical inspection. Our trained personnel examine each cylinder for any signs of damage, such as:

1. Damaged or faulty valves

2. Missing or damaged shrouds

3. Base ring damage - If a cylinder fails to meet our quality standards & procedure requirements, it is promptly rejected and removed from service. Only cylinders that pass our inspection process are filled and dispatched to our customers.

- Dictum sit amet amet justo donec enimties.

- Semper convallis a cras auctor neque vit.

- Lectus quam vel pretium id leo in vitae. Feugiat scelerisque varius morbi enim nunc.

- Dignissim etiam diam quis enim lobortis sceleri.

- Scelerisque vel elit mauris pellentesque.

- Justo donec amet dictum sit amet enimties.

- Auctor neque convallis a cras semper vit.

- Id leo in vel pretium lectus quam vitae. Feugiat scelerisque varius morbi enim nunc.

- Enim lobortis etiam dignissim diam quis sceleri.

- Pellentesque vel elit scelerisque mauris.

- Our dedicated team works closely with customers to ensure that our LPG products meet their specific requirements and are handled safely.

- We consider the unique demands of each customer’s application, whether it’s propane or butane. Our experts provide guidance on product usage, safety protocols, and training programs to ensure seamless integration with our customers’ operations.

- Through regular site visits and collaborative support, we empower our customers to handle our LPG products with confidence and safety. By sharing our expertise and promoting best practices, we foster long-term relationships.

New Technology & New Path

Morbi tincidunt ornare massa eget egestas purus viverra. Orci nulla pellentesque dignissim enim sit amet venenatis urna cursus. Orci a scelerisque purus semper eget duis.

Make Manufacturing Easier

Magna sit amet purus gravida quis blandit turpis cursus. Enim blandit volutpat maecenas volutpat blandit aliquam etiam erat. Tincidunt praesent semper feugiat nibh sed pulvinar.

Perfect Solution

Aliquam id diam maecenas ultricies. Massa enim nec dui nunc mattis. Tortor dignissim convallis aenean et tortor. Purus sit amet luctus venenatis lectus magna fringilla urna.

New Technology

Viverra tellus in hac habitasse platea dictumst. Nisl purus in mollis nunc sed id. Fringilla est ullamcorper eget nulla. Congue eu consequat ac felis donec et odio pellentesque.

Our Portfolio

Recently Completed Projects

Contact Form

Have Any Queries?

Malesuada proin libero nunc consequat interdum. Sed lectus vestibulum mattis ullamcorper. Ultrices tincidunt arcu non sodales neque sodales. Commodo nulla facilisi nullam vehicula ipsum a arcu cursus vitae. Nulla facilisi morbi tempus iaculis.

New Arrival